METHODOLOGY FOR USAGE

- AutoStem Cartridges are simply inserted into a borehole drilled 2/3rds the depth of the oversize boulder

- No stemming is required when using AutoStem products – AutoStem products stem themselves

- No explosive accessories are required when using AutoStem products

- Try to drill with equidistant burdens to the rock circumference

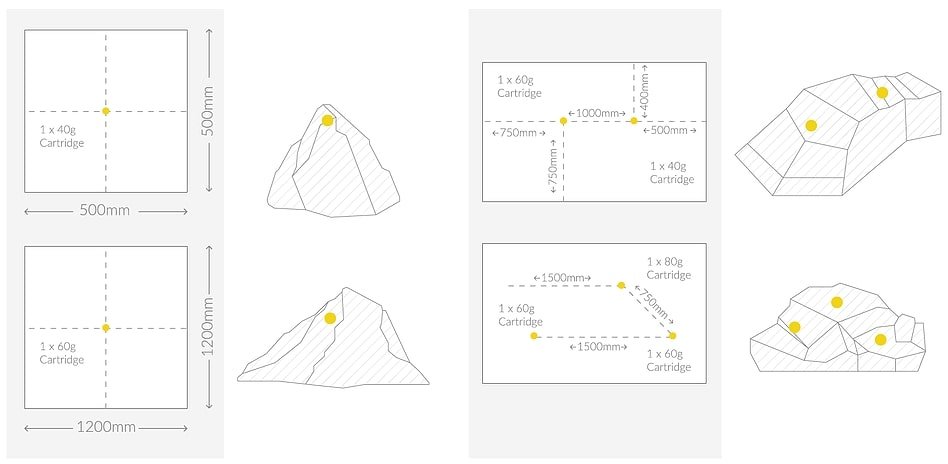

- Ordinarily, use of 40g per cubic meter will be sufficient to achieve fragmentation under 400-500mm

- Make sure the hole is drilled to optimally 66% the depth of the boulder.

- Test cartridges for continuity prior to inserting into the borehole. Utilise approximately 40g per cubic meter.

- Insert cartridge: Whether an operator is using 1 cartridge or multiple cartridges, cartridges should always be connected in series.

- The ends of the cartridge circuit are then connected to an extension blasting wire with a clearance area of 50m.

- From that safe distance, the shot exploder can be initiated, initiating all the cartridges.

- AutoStem Cartridges do not undergo a detonation, the initiation is a deflagration.

The dependable oversize management solution

The AutoStem 35mm range of cartridges presents itself as the lowest cost solution for secondary rock breaking and oversize management available world over today.

Avoiding the otherwise necessary investment and maintenance cost in heavy mechanical equipment, AutoStem products can be used effortlessly without explosive accessories in the safe breaking of:

- Oversize boulders

- Footwall and sidewall obstructions

- Safe slyping in confined areas

- Chairlift installations

- Drawpoint clearing

AutoStem Generation III vs conventional explosives

The video below shows the performance difference between the AutoStem Generation 3 and conventional packaged explosives. Less dust, no flying debris, no shockwave vibration into the hanging- and footwall, AutoStem Generation 3 products can offer you a sensitive blasting solution optimising on cycle times, blasting efficiencies and safety.